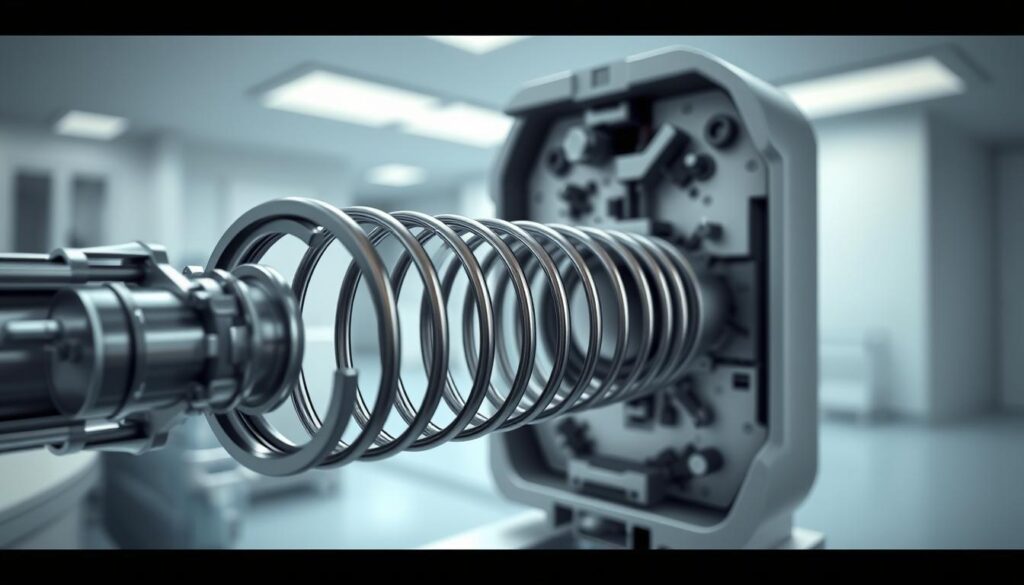

In the fast-paced world of medical technology, precision and reliability are key. Barrel springs play a crucial role, offering the needed force and stability in tight spaces. These springs are made to handle the tough demands of medical equipment, from surgical tools to diagnostic systems.

At the core of medical innovation, barrel springs' design ensures they work well under pressure. This makes them essential for situations where failure is not acceptable.

Barrel springs are key in medical engineering because of their unique design. Their hourglass shape allows for controlled movement and stability. This makes them crucial for precise medical tools.

The barrel spring design is different from regular coil springs. Its tapered shape lets it handle different forces in various ways. This design also helps in keeping devices stable, which is vital in medical settings.

There are two main types of barrel springs. Small ones are used in implants, while bigger ones are in diagnostic tools.

| Type | Design Features | Applications |

|---|---|---|

| Hourglass | Gradual diameter taper | Surgical instruments, pacemakers |

| Cylindrical-Tapered | Hybrid straight/tapered coils | Laboratory analyzers, imaging systems |

At first, medical devices used simple steel springs. Now, barrel spring design uses titanium and shape-memory materials. New technologies like CNC machining and 3D printing make tiny parts for less invasive tools.

These advancements meet ISO 13485 standards for cleanliness and safety.

These traits make sure devices work well in places like operating rooms and patient monitoring areas.

We start by explaining how barrel springs work by focusing on their tapered shape. The curved design combines compression and tension forces into a compact form. This allows for controlled motion in small spaces. Their variable coil diameter creates a progressive resistance curve, which engineers tailor to specific load requirements.

When engineers design implantable devices, how barrel springs work directly impacts performance. The spring’s deflection ratio ensures stable force application during repetitive movements, like in robotic surgical tools. The non-linear spring rate also prevents over-compression, safeguarding delicate internal components.

“Barrel springs outperform traditional coil designs in environments where precision and space are critical,” says a leading biomechanical engineer.

We highlight their ability to maintain structural integrity under cyclic loads—a key factor in long-term implant durability. Their design avoids the sudden force spikes seen in linear springs. This makes them ideal for devices like insulin pumps or prosthetic joints. By balancing load distribution and compression, these springs reduce wear while enhancing operational lifespan.

Barrel springs play a big role in many medical fields. They help solve problems where precision and reliability are key. These parts make life-saving tech better by being strong yet small.

Implantable devices need barrel springs to last long and stay stable. Pacemakers from Medtronic and neurostimulators by Abbott use them to keep energy flowing for years. In spinal fusion tools from Stryker, their ability to resist corrosion stops them from failing in body fluids.

| Device Type | Barrel Spring Benefits |

|---|---|

| MRI scanners | Keep coil alignment during constant vibration |

| ECG monitors | Ensure stable contact pressure on electrodes |

| Laboratory centrifuges | Withstand 10,000 RPM cycles without deformation |

Auto-injectors from Owen Mumford need barrel springs for accurate insulin shots. Infusion pumps from Baxter use them to keep pressure steady for 72 hours. These barrel spring benefits help patients by avoiding dosage mistakes.

Medical device makers have big decisions to make when picking parts. We look at how barrel springs beat out wave or torsion springs in important areas. This shows why best barrel springs are often the first choice for quality and lasting use.

Barrel springs do great in tough sterilization cycles and corrosive places. They stay strong under repeated pressure, cutting down on failures in surgical tools. They also beat stainless steel torsion springs in keeping out corrosion in wet devices.

| Component Type | Fatigue Resistance | Expected Cycle Life |

|---|---|---|

| Barrel Springs | 98% retention at 100k cycles | 250,000 cycles |

| Wave Springs | 75% retention at 50k cycles | 120,000 cycles |

| Torsion Springs | 85% retention at 80k cycles | 180,000 cycles |

Best barrel springs save money in the long run because they last longer. They meet ISO 13485 standards for medical-grade materials.

Our study shows best barrel springs offer the best value in performance, lasting power, and cost. Device makers should focus on these to make the best choices.

When looking for barrel springs for medical devices, it's crucial to choose trusted . Our experience shows that there are three key things to look for: certifications, material knowledge, and clear manufacturing processes. Make sure the barrel spring manufacturers have ISO 13485 and FDA guidelines. These standards are important for keeping things clean and safe for use in the body.

| Selection Factor | Key Requirements |

|---|---|

| Certifications | ISO 13485, FDA 21 CFR Part 820 |

| Materials | Biocompatible alloys (Elgiloy, titanium) |

| Testing | Continuous fatigue testing, chemical composition analysis |

| Collaboration | Design for manufacturability reviews |

Good barrel spring manufacturers work with you from the start to the end. They should offer to help with design and provide samples with full certifications. They also need to have a reliable supply chain with systems for quick delivery and backup plans. By choosing suppliers that meet these standards, you reduce risks and make sure your devices work well over time.

Barrel springs are key in medical device innovation, offering precision and reliability. As devices get smaller, there's a big need for tiny, precise springs. New methods like metal 3D printing and nanotechnology help make these springs.

New materials like high-performance alloys and composites are also important. They help springs last longer and resist corrosion, which is crucial for implants and surgical tools. Finding the right barrel springs means working with suppliers who use these new technologies.

Looking to the future, barrel springs will be crucial in advanced medical tools. They will help in robotics-assisted surgeries and wearable health monitors. Their ability to adapt makes them essential for smart implants that adjust to patients' needs.

Our research shows that investing in R&D and material science will improve performance. Medical device companies need to choose suppliers who are experts in custom spring design. This way, the industry can meet future challenges while keeping patients safe and devices reliable.

Barrel springs have a unique hourglass shape. This shape allows for graduated compression and variable spring rates. They differ from regular springs by offering better stability and performance in tight spaces. This makes them perfect for medical use.

There are several types of barrel springs for medical use. These include cylindrical, tapered, and double-barrel springs. Each type is made for different needs, like load capacity and space in medical devices.

Barrel springs work due to their special shape. This shape affects how they compress and distribute force. Their non-linear spring rates offer progressive resistance, making them great for smooth actuation in surgical tools and precise use in implants.

Barrel springs offer many benefits in medical devices. They provide consistent force, are durable, and fit in tight spaces. They are also biocompatible, making them safe for sensitive uses. Their reliability is key for life-saving medical tech.

To find top barrel spring suppliers, look for ISO 13485 certification and FDA compliance. Check their experience in making medical-grade materials. Also, evaluate their manufacturing, quality control, and design support.

The design of barrel springs is very important. It affects their mechanical performance, like fatigue resistance and load handling. Good design ensures springs work well over time and under different conditions, crucial in medical settings.

Yes, barrel springs can be tailored for specific needs. This includes size, load capacity, spring rate, and material. Customization ensures springs fit the exact needs of medical devices, enhancing performance and reliability.